My found machine was a coffee urn. I began the process by taking the machine apart. Initial ideas about about what property I wanted to use in the machine was heat, and steam, from the coils that are layered between the outside sheet of metal and the inside one. I was hoping to be able to access the coils from the bottom of the machine. However, after removing all screws on the bottom plate, I realized that it was welded on and the screws were used to hold together internal pieces of the machine. Taking out the screws set lose some of the internal parts, and the coils were not working. From here, I decided to focus instead on a working, and easy accessible part, the valve.

I was interested in the restriction ability that the valve had. It could change the amount of liquid in the urn, but only by moving to smaller amounts. I wanted to track the change of the liquid in the urn, and decided to put paper inside the urn and use dyes that would leave water marks.

I wanted the choice of when the valve was open and for how long to not be directly connected to me. I connected the valve to a sliding door, so that when ever the door opens the valve opens, and when the door is closed the door closes.

The dye I used was pickled beet juice because there was no dye in the house, and because there was a lot of beet juice. I also put in orange zest and coffee grounds. The orange zest and coffee grounds floated, and stuck to the sides, highlighting the water lines.

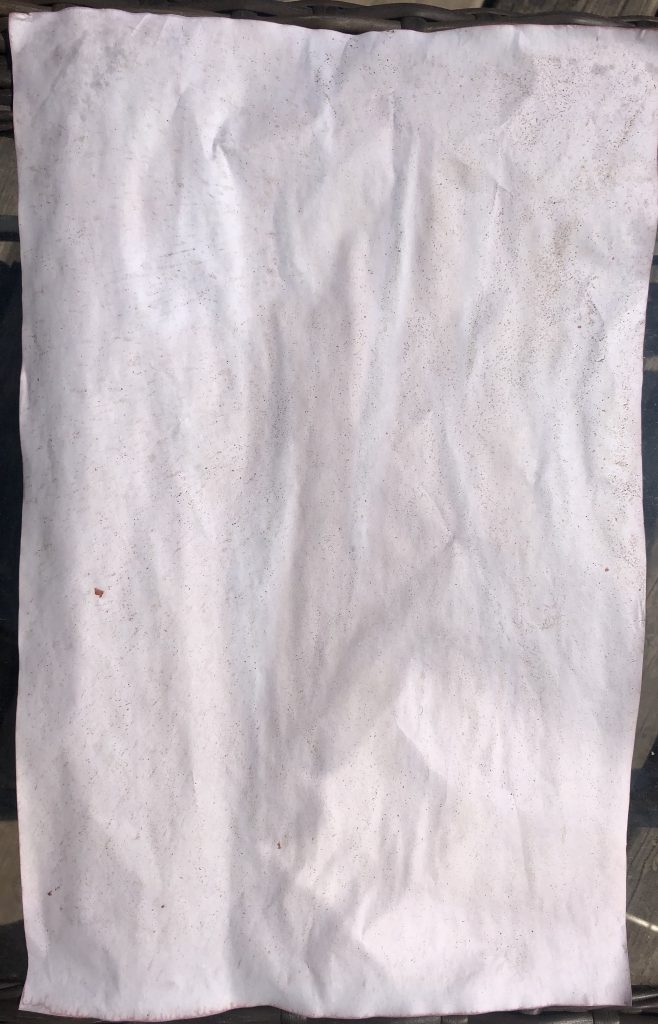

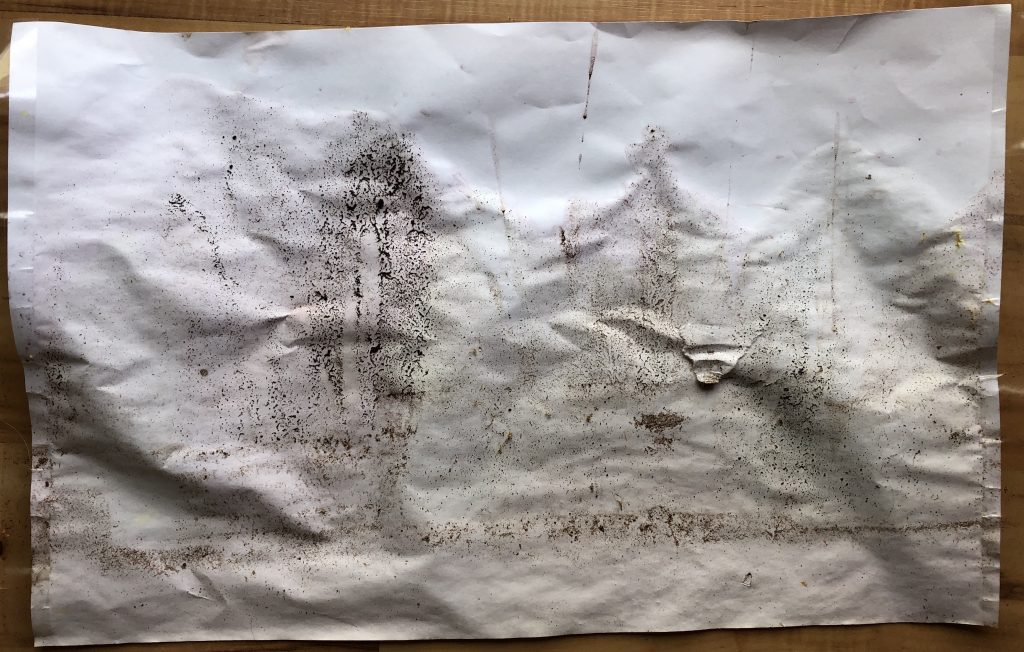

The image below is the paper after all of the beet juice, zest, and coffee grounds had been emptied out of the urn. It lasted about one and a half hours. The bleeding stains at the top of the image are from the juice sloshing up the sides when I adjusted the position of the urn.

There were a few problems that I had to address throughout the process. The first was putting the ‘witches tower topper’ iron thing in the urn to give it more weight so it did not get pulled with the door. Another was that I wanted the door to be accessibleX so it could be used with out having to adjust or move around the urn or string. This I never really figured out. The position of the urn and string that pulled the valve when the door was open and closed it when it was closed ,put the urn and string directly in the way.

For the second round, I added a new liquid in the middle of the process, pickle juice and coffee grounds, because, might as well stay with the food trend. The original beet/coffee/zest liquid was used in the beginning. As well as putting paper inside the urn I also put multiple sheets of paper under the spout to capture the pattern there.

I re-did the set up so the liquid could fall for some time before hitting the paper. Also, with out placing the urn off the ground, it would be hard to fit a piece of paper under it. Initially the paper was on a cookie sheet, but I eventually set it directly on the deck so excess could runoff and keep the patterns distinct.

The second round paper had less water level marks, and is less methodical, which makes sense because of the less methodical process. The system ran for 2 and a half hours this time. What the internal paper shows in the sound round is more of how poring the liquid down the sides affects how the sediments (zest and grounds) stick.

I was never able to get the set up to work so that the door was usable with out someone bending and ducking. The position of the urn and angle of the sting were the variables that contributed to the valve opening. Finding a placement of the urn and angle of the string that opened the value and made sure the system was out of the way., was not something that either round accomplished.

The second round is almost more of an examination of how water flows through sediments, and what marks flowing, grainy water leave. Experimenting with this found machine taught me that developing ideas takes action and experimentation with the machine. A success of the machine is due to the hands off nature of its operation. If I was more involved, or the machine relied on me more during the process, I think the results would be less organic. What I mean is that by kind of giving the machine a mind of its own, the final products are less expected and more unique. They are something that I could not think up of on my own, because something else ‘thought’ them up.